To model the thermal loads in LIRA-CAD module of the program, use the specialised tools available on the "Analytics" tab, on the "Analytical load" panel, in the "Loads" drop-down list (see Fig.1 ).

Thermal loads can be of two types:

- Thermal load on bar (applied to beams and columns).

- Thermal load on plate (applied to walls and slabs).

When a thermal load is defined to a pre-existing structural element (such as a slab or column), the thermal load is automatically linked to the element if its contour is created on the analytical model of this element.

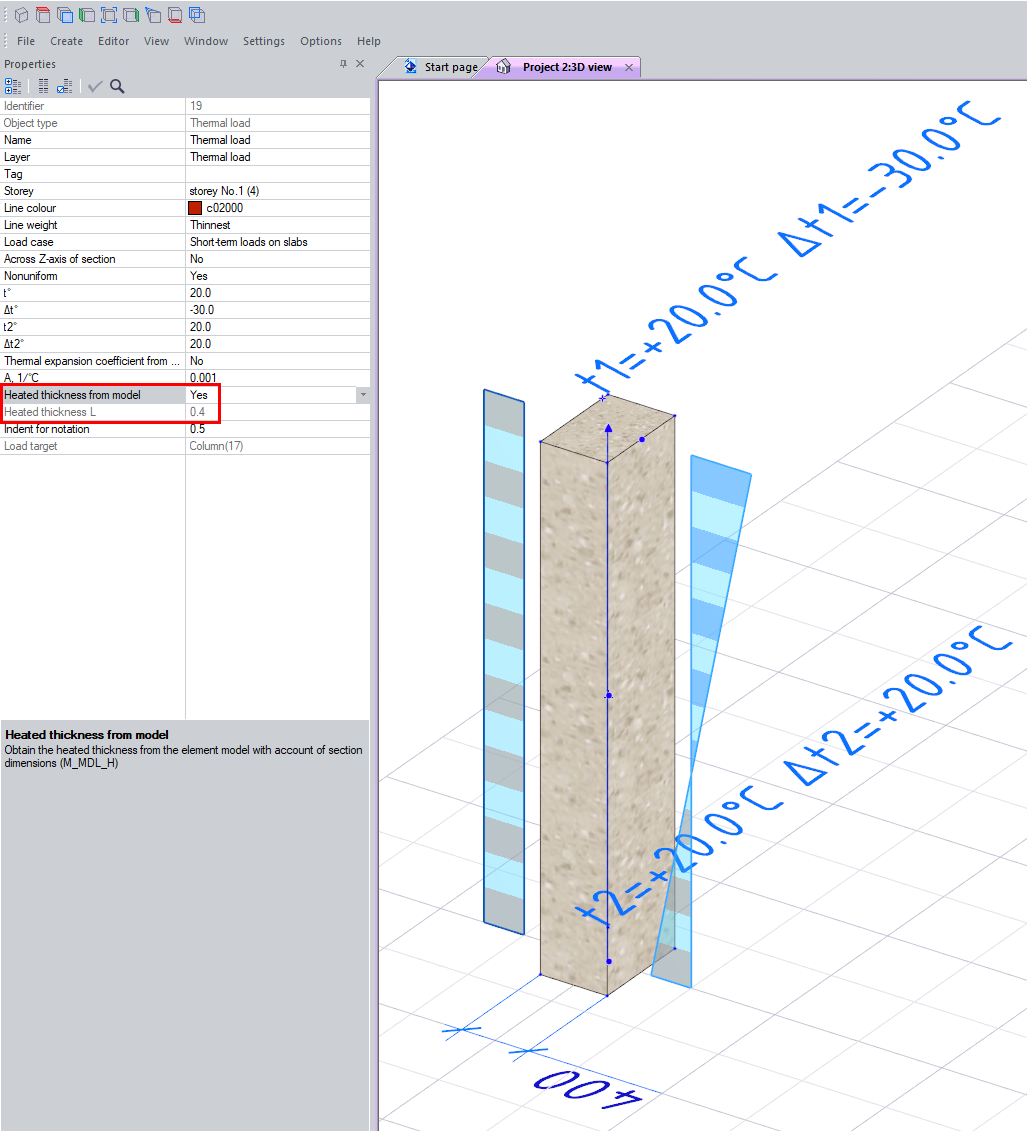

To make sure that the thermal load is applied to the certain element, sel ect the load, and in the "Properties" window, see the "Load Target" parameter (see Fig. 2).

This read-only parameter identifies the specific structural element that the load is associated with and, thus, influences.

The thermal load is not exported to the VISOR module if it is not applied to any element of the model. To apply the thermal load to any structural element, it is necessary to sel ect this load, sel ect the element, and activate the "Apply thermal load" command located on the same drop-down menu (see Fig. 1).

The thermal load applied to a specific structural element can obtain the linear thermal expansion coefficient "A" fr om the material properties assigned to the structural element. To activate this option, use the "Coefficient of expansion fr om material" parameter in the "Properties" window. If the option is activated ("Yes"), the coefficient value is displayed in the table for read-only reference. It is possible to modify the coefficient in the properties of the material assigned to the slab. If the option is not activated ("No"), the value "A" can be set directly as a parameter of thermal load. In this case, it may be modified and then passed on to the analysis.

One thermal load may be applied to several structural elements (see Fig. 3). In this case, the load on each finite element can have a different value, "A", depending on the material assigned to the slab in which the FE is located. Or it may be a common value if the "A" coefficient fr om the load properties is used.

For the thermal load, you could define the same properties as in the VISOR module.

Depending on whether the element's centre is inside the load contour, the load will either be applied to the finite elements of the design model or not.

It is also possible to define some additional properties and options.

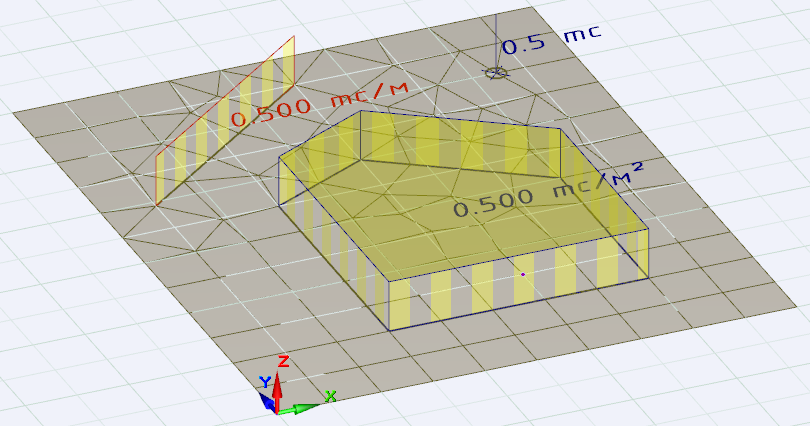

For instance, two values of temperature and temperature difference can be defined instead of only one. To do this, sel ect the "Nonuniform" option and you will be able to define two pairs of values at the check points. Accordingly, a thermal load nonuniformly distributed over the slab area will be generated (see Fig. 4). For each FE within the load contour, the temperature and temperature difference are calculated by interpolating these values for the area wh ere the load is applied to.

The "Apply in triangulation" option ensures that the configuration of the finite element depends on the load contour; each element is either completely inside or outside the load action.

This option can be used not only for thermal loads, but also for standard loads. It may be applied to loads distributed across the area or along the line, as well as to concentrated loads. For a concentrated load, a node will be created at the place where the load is applied (see Fig. 5).

For this option to be available, the load should be associated with a slab (or wall).

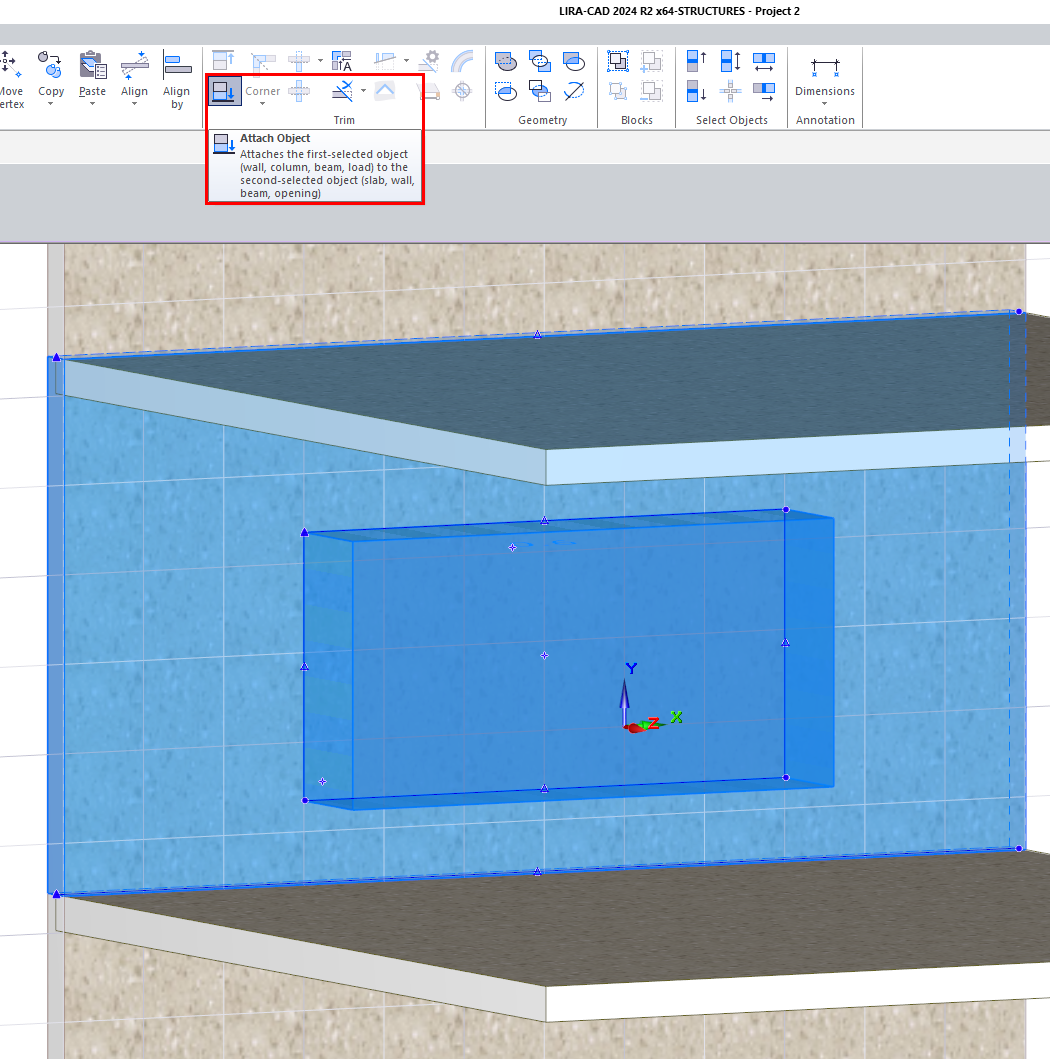

To attach a standard load to a slab or wall, follow these steps:

- Sel ect the load (Fig. 6).

- Sel ect the wall.

- Activate the "Attach object" command.

To make sure that the load is attached, in the Load Properties window, see the "Load target" parameter or use the "Manage links of object" dialog box.

To ensure that distributed loads are not converted into a concentrated loads when transferred to the analysis, and remain as uniformly (or nonuniformly) distributed over the area of the finite element, sel ect the "By whole finite element" option. This option is available only for loads that are attached to some structural elements. Note that surface loads can only be attached to plates. Linear loads can be attached to both bars and plates. The triangulation depends on the concentrated load: at the place where the load is applied, a node of the FE design model is generated.

For the thermal load on the bar, there is an option "Heated thickness fr om model". When this option is enabled ("Yes"), the heated thickness is determined automatically and displayed in the table as the read-only parameter. The value depends on the section dimension in the direction of load. If a different value is required, this option should be disabled (the corresponding load parameter is "No").

The "heated thickness" calculated by the model depends on the direction of the thermal load, managed by the option "Across Z-axis of section": "Yes" / "No". The dimension of the section contour in the selected direction is used as the heated thickness.

If you find a mistake and want to inform us about it, select the mistake, then hold down the CTRL key and click ENTER.

Comments